“Working with Spatial has been pleasant and effortless and we’ve found it easy to work with their components. And we would wholeheartedly recommend Spatial for similar development efforts” -- Bertil Thorvaldsson, Product Manager, Software Products ABB Robotics Division

Industry: Robotics, CAM

Product: 3D ACIS Modeler, 3d InterOp Translators, 3D Defeaturing

Challenges: To develop its own geometry engine would have been a very large project well out of the realm of ABB’s core competency of robotics.

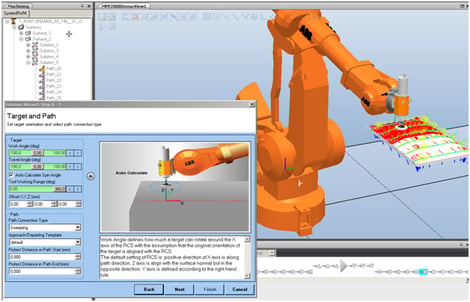

Solutions: Spatial ACIS 3D modeling engine chosen because it’s the gold standard in the industry and is very easy to integrate into ABB’s RobotStudio. In addition Spatial’s InterOp CAD translators make it easy for ABB to provide solutions for customers that want to convert data from their existing CAD systems into an SAT format.

Results: Relieves the burden to implement modeling functionality and manage geometry; large savings of effort to license components as compared to developing it in-house. System integrators and end user customers are able to increase productivity.

ABB Robotics Division

ABB is a technology-based provider of power and automation products, systems, solutions, and services. Its Robotics Division is a leading supplier of industrial robots, robot software, peripherals and services for manufacturing. Key markets include automotive, plastics, metal fabrication, foundry, electronics, machine tools, pharmaceutical and food and beverage industries. ABB has installed more than 250,000 robots worldwide.

ACIS, 3DScript and SAT are registered trademarks of Spatial Corp.